Entering Linear Steel

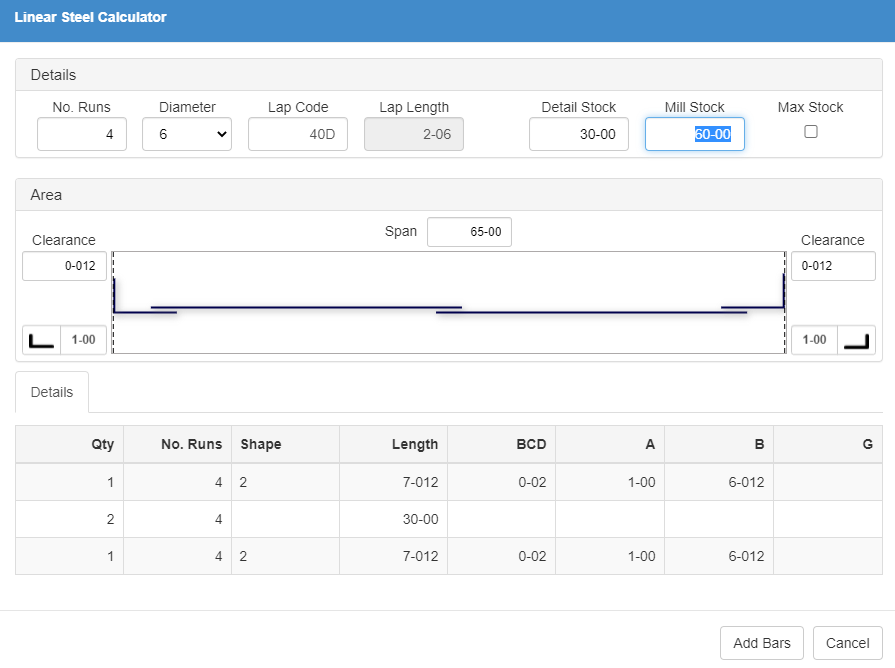

Use Linear Steel to take off a run of steel in one direction, such as footings or walls. Based on settings that you define and the given length, the program automatically calculates the required number of stock and piece-out bars for the linear run.

Taking off a Linear Run

To take off linear steel:

- Click Tools > Linear Steel.

The Linear Steel Calculator displays.

- Complete the Linear Steel takeoff fields, described below.

The program develops the required bars for your run(s) and displays them in the Details grid. - Click Add Bars.

The bars are added to the main Line Entry screen.

Linear Steel Field Descriptions

No Runs

Number of linear runs. For example, if you have 4 bars running the perimeter of a footer, number of runs is 4.

Diameter

Diameter, or bar size, of the bars in the run.

Lap Code

Number of bar diameters or lap table entry. The value set up in the Engineering Defaults screen > Building Standards frame displays by default. When you enter a lap code, the calculated length displays in the Lap Length field. If you do not enter a lap code, you must enter a Lap Length.

Valid Entries: Lap code value as described in Entering Laps.

Lap Length

Display-only: Length of the lap based on Lap Code entry, or

If you did not enter a lap code, enter a length in this field.

Valid Entries: Display-only or length value. Refer to Entering Lengths.

Detail Stock

Stock length bar used for detailing purposes. In general, the program will calculate a series of detail length stock bars plus a piece-out bar to cover the linear distance. See the note below.

Mill Stock

Maximum length of bar you will supply. See the note below.

Note: In certain scenarios, the program will provide a bar that is a slight percentage longer than the detail stock in order to save a lap. It will never provide a bar that is longer than the mill stock.

Max Stock

Determines how stock and piece-out bars are developed:

- Checked - Stock length bars developed left to right with a piece-out bar at the (right) end.

- Un-checked - Equal-length piece-out bars for the left and right ends are developed with the required stock bars in between.

Clearance (Left and Right)

Distance from the bar to the edge of the concrete. This value is subtracted from your length field entry.

Valid Entries: Length value. Refer to ???Entering Lengths.

Hook (Left and Right)

If the bar has a hook, click and select the hook type.