Understanding Work Orders

A work order is used to create fabricated components for an assembly.

Work orders are similar to regular orders in many ways.

- You create and edit work orders in Order Entry.

- You schedule work orders for fabrication in Scheduling.

- You process work orders and create tags for work order items in Processing.

Because work orders are a step in creating a new final product, work orders differ from regular orders in the following:

- You cannot schedule work orders for delivery.

- You cannot load or validate loading for work orders.

Processing Work Orders

When you add a work order to a Processing run, Processing creates item tags for each component AND an inventory tag for the assembled stock product.

In the Material grid, kit items are preceded by a symbol:

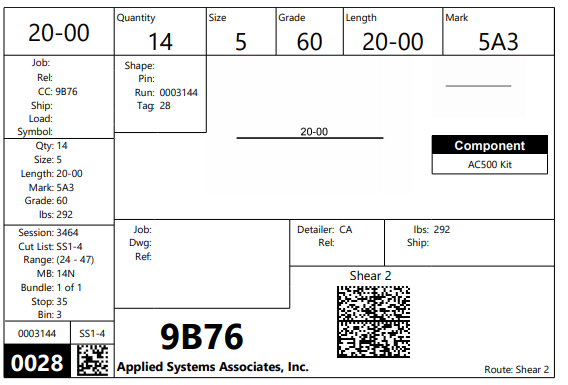

Component tag

Component tag

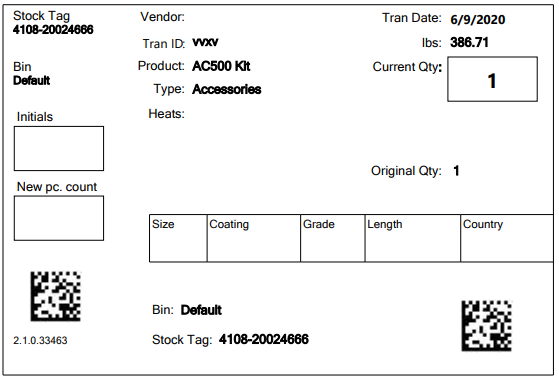

Assembled kit inventory tag

Assembled kit inventory tag

In general:

- Use the component tags to identify and fabricate the component items.

- Use the inventory tag to identify the final stock product after it has been assembled.

HINT: Later, when the product is shipped to a customer, you will scan the inventory tag to relieve and track your on-hand inventory.

Sample Stock Kit Component Tag

Sample Stock Kit Inventory Tag