Working with Delivery Stops

A delivery stop, sometimes called a "drop," refers to a specific point at which material is to be unloaded at a jobsite. Stops are ordered sequentially. For example:

- If all material on a load is being delivered to the same location, it only has one stop: Stop 1.

- If material is being delivered to two different jobsites (or two different areas of the same jobsite), it has two stops: the first is Stop 1 and the second is Stop 2.

When you add material to a load, the system automatically creates stops by grouping all material from each job onto its own stop. Load reports list stops in sequence. You can easily change the order of your stops.

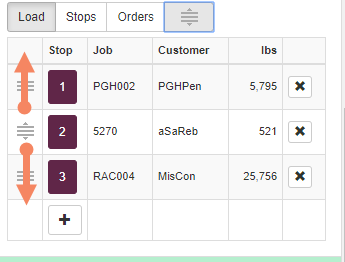

To resequence stops for a load:

- On the Load card, click Stops to view the Stops grid.

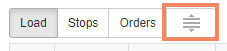

- Click Sequence .

A Sequence tool displays at the beginning of each row.

- Click and drag the rows into the desired sequence.

- Click the main Sequence tool again.

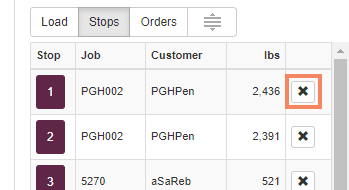

To delete a stop:

- On the Load card, click Stops to view the Stops grid.

- Click Delete in the Stops grid to remove a stop.

Note: All material associated with the stop is removed from the load. For example, if control code AAA1 is on Stop 1, when you delete Stop 1, control code AAA1 is deleted from the load.